Dust Control Control Solutions for the Construction and Mining Industry

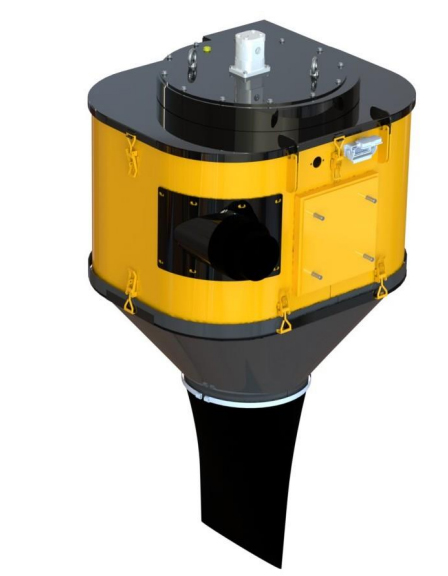

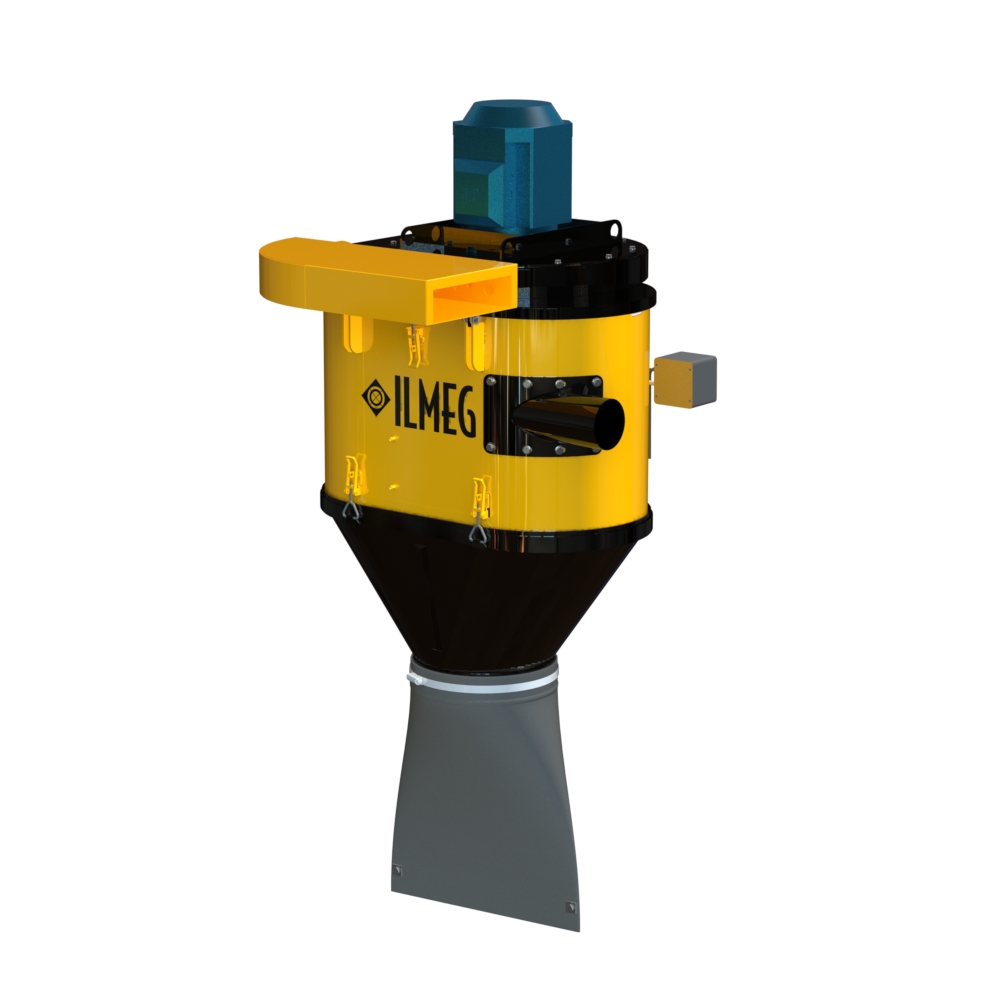

X-100

Max hole size: 100 mm (4”)

Filter area: 8 m²

Number of filters: 2

Oil flow requirement: 22 l/min

Oil pressure requirement: 200 bar

Width x depth x height: 740 x 957 x 1062

Approx weight: 160 kg

Filter cleansing system: Reversed air through filters in sequences while drilling.

Rec. working pressure: 7 Bar (100PSI)

Optional Equipment:

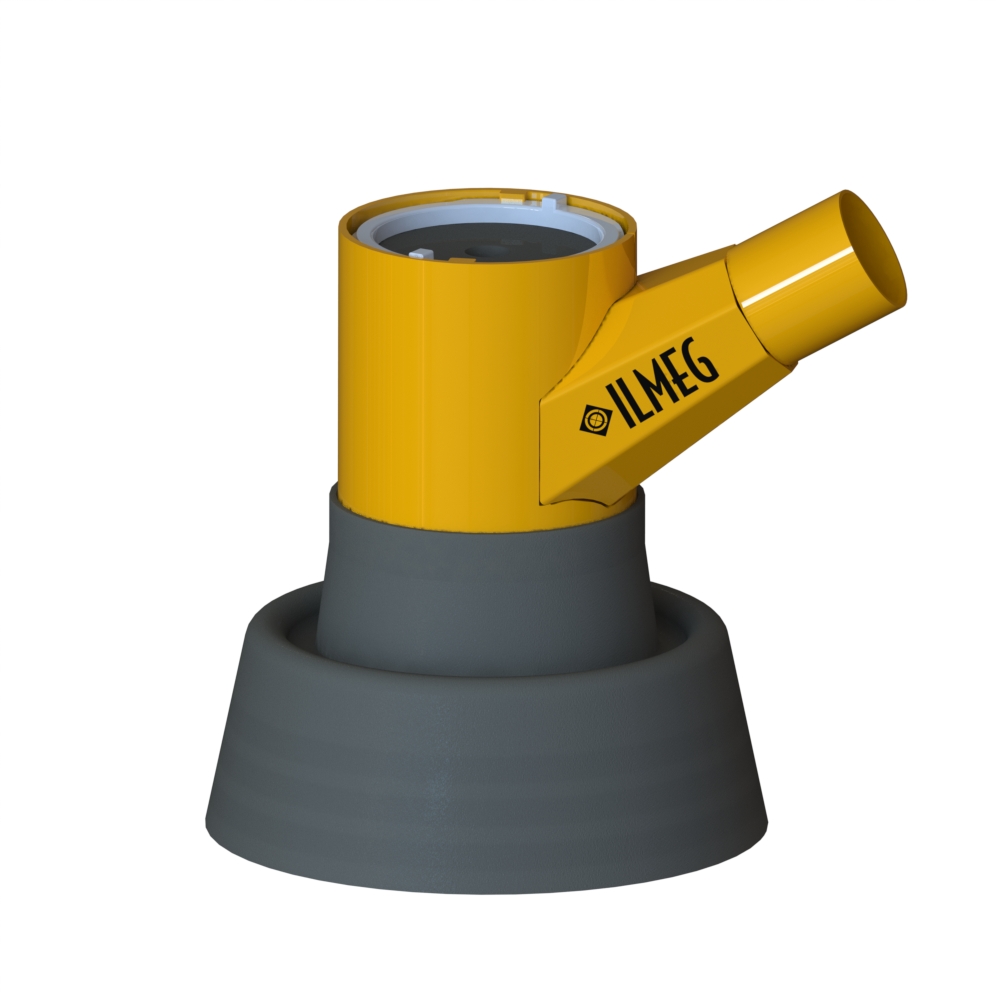

Pre-skimmer

BHS-100 Bag handling system

Filter area: 8 m²

Number of filters: 2

Oil flow requirement: 22 l/min

Oil pressure requirement: 200 bar

Width x depth x height: 740 x 957 x 1062

Approx weight: 160 kg

Filter cleansing system: Reversed air through filters in sequences while drilling.

Rec. working pressure: 7 Bar (100PSI)

Optional Equipment:

Pre-skimmer

BHS-100 Bag handling system

Download leaflet Accessories

Features

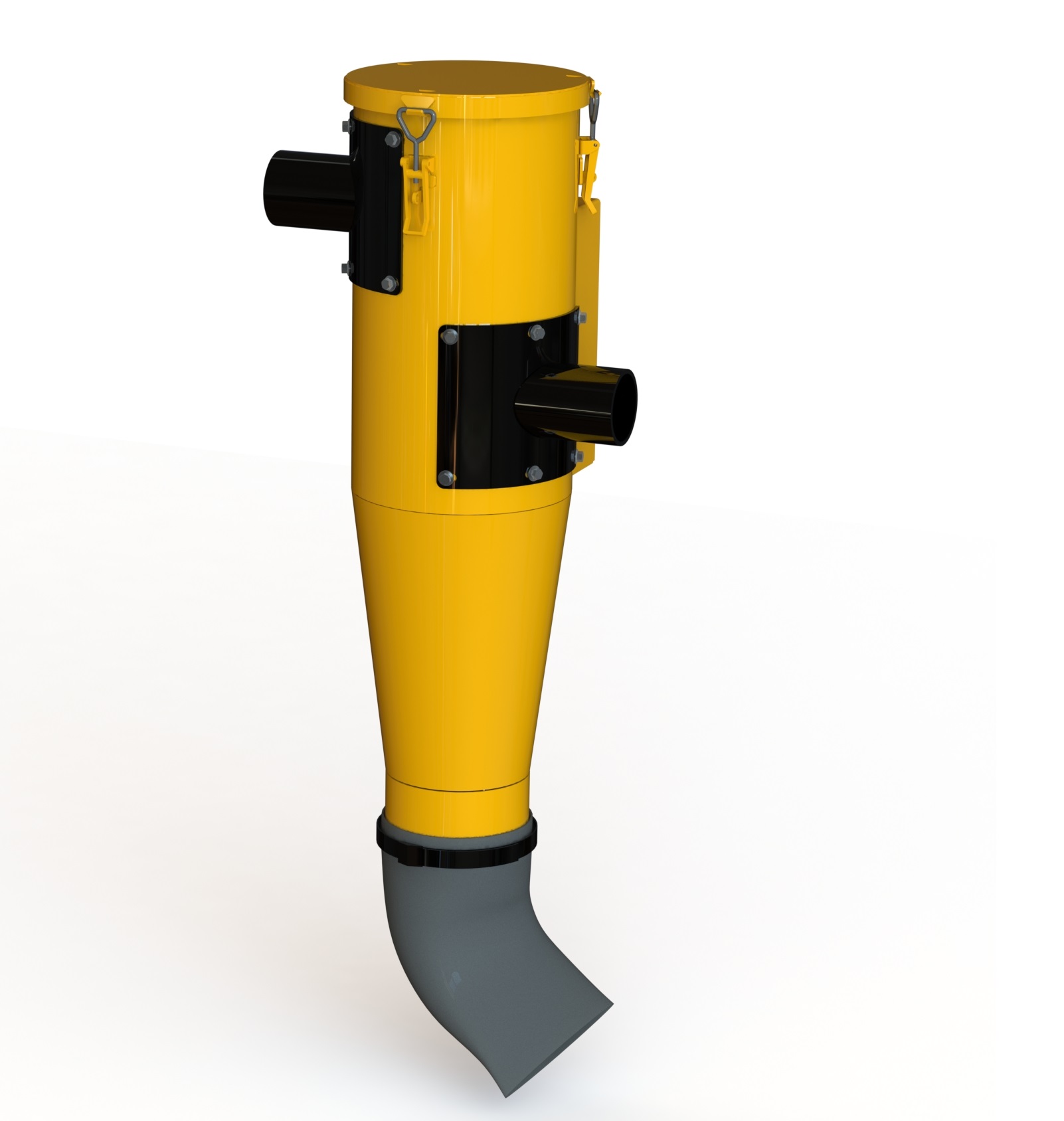

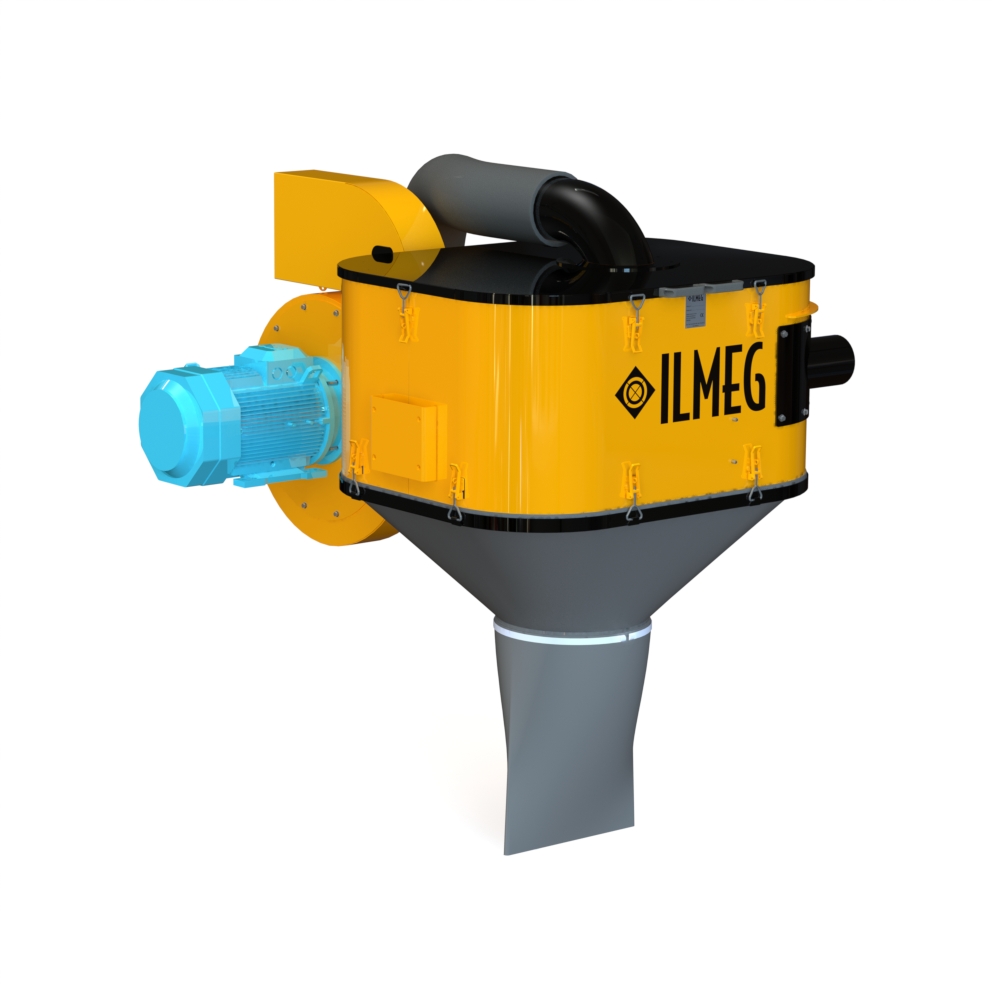

Heavy duty cutting

The heavy duty cuttings collector is specially designed to reduce the dust to the minimum.

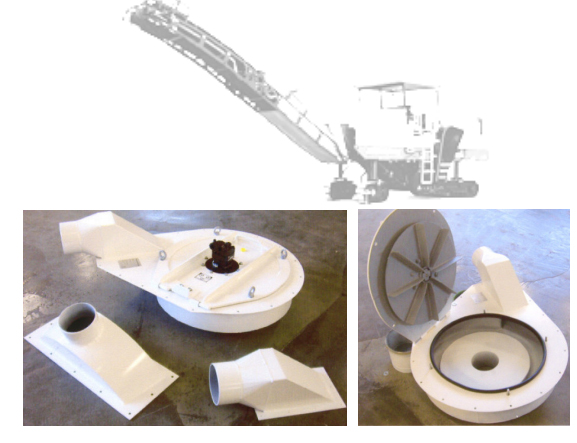

Suction fan design

The suction fan design, impeller and housing, limits the maximum power requirement to correspond to the need in each application. The result is lower sound and lower power consumption than a traditional dust collector.

Easy access

Easy access of filters and air valves by opening the top, the clean side of the dust collector. Filter exchange is made in a couple of minutes

X-series Hydraulically Powered Dust Collectors for Hole Dimensions up to 203 mm

H-Series Hydraulically Powered Dust Collectors for Hole Dimensions up to 102 mm

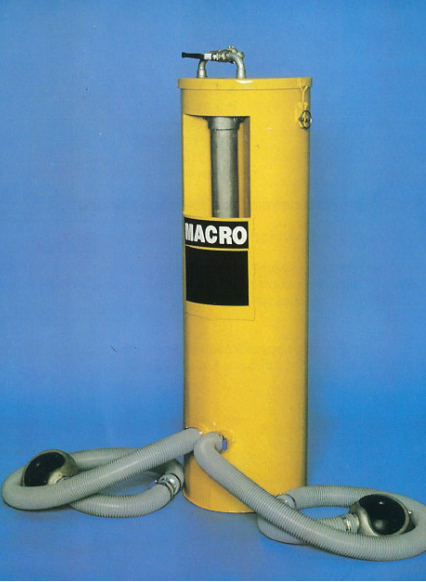

Fully Pneumatic Dust Collectors For Hole Dimensions Up To 140 mm (5 1/2")

Zero dust systems

Asphalt Fume- and Dust Control System

Precision Drilling Instruments

Accessories

X-E-series Electrically powered Dust Collectors for Hole Dimensions up to 203 mm

XR-Series Dust Collecotors for Rotary Drills